EDM in Precision Machining: A Game-Changer for Complex Parts

While the subject is less complex, consistently formative, Electrical Discharge Machining (EDM) has become among the most revolutionary manufacturing processes. And as more of the higher profile industries like aerospace, medical devices, and automotive push the tolerance and geometrical dimensions of parts, EDM reemerges as that pivotal technology. With high leverage on this advanced process, China machining service providers are considered to be global trend-setters in delivering highly accurate and precision machined components. In this article it is our aim to elucidate why EDM represents a breakthrough for precision machining when it comes to the creation of intricate parts.

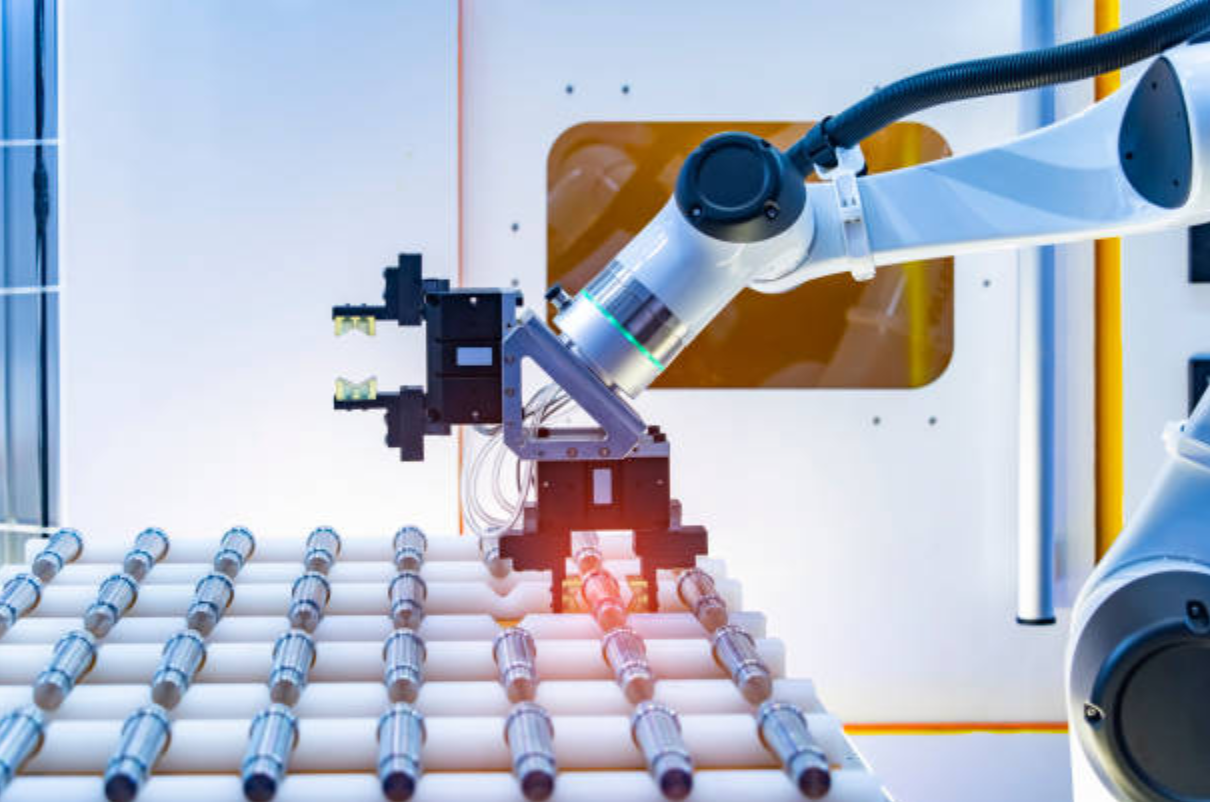

Precision Machining EDM

The technique of Electrical Discharge Machining (EDM) is a process, where no direct contact between the tool and material is brought into operation, but rather sparks are used to perform the operation in dealing with conductive workpieces. An ultra-thin knife-shaped electrode that operates at a high voltage and the workpiece is submerged in a dielectric fluid to maintain stability of the process and improve its accuracy. This method is especially useful in the removal of metal such as titanium, tungsten and hardened steel and other difficult to-machine materials.

Unlike most traditional machining methods that apply mechanical stress to accomplish precision and intricate shapes, EDM can produce impressive tolerance and exquisiteness of shape. Due to this, it finds widespread application in instances where the components may be sensitive or require intricate work such as prototyping. EDM is typically applied to carving complex geometric features like sharp edge and micro features, along with inherent material properties. Chinese machining service providers adopt it to ensure that the parts supplied conform to the industry standards for integral and adhesive uses across many applications.

Benefits of EDM for Complex Parts

EDM has innumerable benefits when it comes to creating intricate shapes, which has helped turn it into a favoured technology with high tolerance calls for. This one benefit is that the tool is capable of working with complex geometries and fine tolerances that are difficult for conventional machining. For such intends, a wide range of geometry can be achieved such as producing sharp corners, thin walls and finessed outlines with an unparalleled precision.

Further, EDM can machine hard and brittle materials without distorting them or generating mechanical stresses on its surface. The process reduces heat affected zones thus the material structure as well as properties of the material are retained. These features make EDM indispensable for some specific industries, for example aerospace, medical devices Industries, etc. Working with edm manufacturers and machining professionals from China guarantees that all projects in every level of difficulty will be accomplished promptly and with optimum quality.

The last, but not the least, is the advantage of cost effectiveness of EDM. This increased accuracy and precision on the surface is another big advantage that EDM provides over traditional methods that often require time consuming processes such as polishing and grinding. This not only makes the use of resources easy but also provides for uniformity in quality produced in the batches. EDI is extremely useful for performing complicated operations and especially for working with such materials as titanium.

Usage of EDM in Precision Machining

The versatility of EDM therefore calls for its uses in many applications. In the aerospace industry, EDM apps are employed when developing the blades of the turbines; engine elements and other fastener components that are strong and rigid necessitating strict quality control and close tolerances. In manufacturing, EDM is used in creating surgical instruments, implants, diagnostics, and other tools in which fluctuation margin, surface finish and precision are vital.

In the auto industry, the pressure Die Castings are vital, where the EDM is used in the manufacturing of delicate auto transmission parts, molds and dies for proper fitness and long lasting performance. In addition, applications of EDM are also seen mainly in the electronics industry for manufacturing of micro-components, connectors and circuit boards with fine features. Due to the cooperation with a China machining service provider, businesses can rely on EDM solutions developed and optimized for specific industries of operation and ensure reasonable cost and reliability.

Superior Surface Finishes and Efficiency

EDM has emerged as one of the most versatile techniques for obtaining excellent surface finishes simply. A distinct feature of the process is high surface quality, making it possible to reduce or completely omit refinishing works. This capability is fundamental to components in businesses such as the medical device and electronics industries where the surface finish determines performance.

In addition, EDM important advantages are high accuracy and negligible manufacturing time compared to other conventional methods and, thereby, minimum material loss. Thus for the business organizations that desire to enhance their production processes, the Chinese machining service providers present vast EDM solutions that interrelate between the advanced technological frameworks and craftsmanship. These providers understand that all parts have to be top quality, right from the first pre-production prototypes through to volume production.

Choice the China Machining Service for EDM

The accuracy in China’s manufacture, including high technology, professional technical personnel, and comparatively low prices, makes China the world’s leading country in the precision machining business. As for the China machining service provided, the EDM works with other advanced machining methods that allow it to yield unparalleled capabilities. These services fit the demands of various and complex industries by offering quality work within the indicated time and cost constraints.

The expertise of the EDM manufacturers coupled with CNC machining specialists in China provide companies with modern technology and best strategies. These providers excel at addressing your complex designs, fine geometry, and high-performance materials with guaranteed reliability and efficiency at every phase. They also have the advantage of being scalable, it is possible to handle a small prototype in the same manner as handling bulk production with-out compromising on quality.

Lastly, EDM has displaced conventional processes of precision machining through creating the ability to manufacture intricate components with high tolerance and standard. EDM is not just a game changer in today’s manufacturing world, it opens up new avenues of innovation and performance when done in conjunction with China machining service suppliers. EDM is one of the future manufacturing technologies that offer versatility and precision coupled with reasonable costs as to be used in near net shape applications.