Creative Uses for Custom Metal Brackets in Architectural and Industrial Design

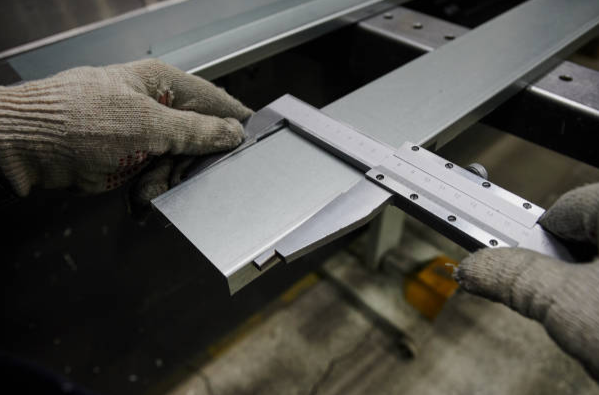

Custom sheet metal fabrication allows sleek and precise construction of various structural components which architects and industrial designers incorporate into their projects. This innovation gives them the opportunity to specially craft solutions for specific structural challenges. Custom brackets are metal pieces that are integral to the design and serve both aesthetic and mechanical purposes. Custom brackets are critical components in modern designs of contemporary buildings as well as in the designs of robust industrial structures. In this article, we highlight some of the custom brackets’ applications and their impact on architectural and industrial design, emphasizing the role of custom sheet metal fabrication in giving those brackets their functionality and versatility.

The Contribution of Custom Metal Brackets in Architecture Design and Construction

Custom metal brackets serve critical purposes in modern architecture by contributing to construction functionality and providing aesthetic appeal. Custom brackets are increasing in use among self-supporting structures as in building architectural forms. These metal pieces can form part of window frames, as well as numerous other external decorations that improve the image of the building.

The melting of modern architecture with floating structures using custom metal brackets is by far one of the most newfangled structures. These brackets are meant to support cantilevered floors, overhangs, or balconies while still allowing them to be visually lightweight. Custom sheet metal fabricating makes sure that these brackets are bespoke such that they take into account the design along with the weight and do not compromise visual appeal.

Moreover, custom glass facades have minimalistic modern appeal and simple elegance in custom metal brackets. While concealed, these brackets serve the custom design's more powerful versatile use and flexibility, serving as tools that defy the traditional design boundaries.

Custom Metal Brackets in Industrial Fields

While custom metal brackets are fundamental in architecture, they serve great purpose in custom industrial design, where strength and durability reign supreme. Sectors such as construction, manufacturing, and heavy machinery use custom metal brackets to support a multitude of equipment and structures.

Vibration isolation pads help to prevent unwanted shaking by entire pieces of machinery as well as help with relative motion between the rigid structures and other supporting elements. It is often beneficial or necessary to attach or weld them directly to the machine capsule outlines or to detail housing of moving parts. For instance, beneath the industrial pipes It is critical to ensure that an adequate level of security is in place to avoid machines' slippage and posture while simultaneously waving their arms around.

On the other hand, blanking, punching or laser cutting holes on a piece of sheet metal is very cost-effective when it comes to “cutting a rectangle out of a rectangle”. These practical pieces can be used for almost every system built for easier horizontal and vertical expansion, facilitating adjustment of geometry and silo structures. These brackets help ensure that the industrial operations are conducted smoothly and in the most safe manner while enhancing the use of space within reach.

The Benefits of Custom Sheet Metal Fabricating

Custom sheet metal fabricating gives metal its creativity and shape. The precision techniques involved in custom sheet metal fabricating offers the production of metal brackets that match the precise requirements of a certain project. This process provides several advantages that include: Tailored Designs: Custom sheet metal fabricating makes it possible to tailor the brackets to specific architectural or industrial requirements. The capability to adjust the brackets to the size, shape, and material guarantees effectiveness in the scope of the entire project. Durability: Custom sheet metal fabricating creates metal brackets with unmatched durability. They can endure extreme conditions and heavy weight. Those brackets will remain functional for many years without any wear and tear in architecture or industry. Cost-Effectiveness: Custom metal brackets may appear costly at first, but the efficiency and accuracy of custom sheet metal fabricating in the process, shift costs from repairs and replacements in the long-term.

Improved Appearance: Designers can create brackets to suit the project’s custom desired sharp and clean lines or decorative design with custom sheet metal fabricating. These brackets serve to improve the appearance of any structure without sacrificing strength, and function, or aesthetics.

Custom Metal Brackets in Eco-Friendly and Sustainable Design

The custom brackets with eco-friendly designs are playing a major part in design because there is a noted need for sustainable design in the current world. Custom eco-friendly designs made from recycled materials and ones developed to minimize waste in production processes are favorable for the environment.

With the custom sheet metal fabricating, architects and industrial designers can produce components which have desirable functionality and are also environmentally friendly. For example, custom metal brackets can be designed to increase energy efficiency by improving a building's thermal insulation. Brackets can also be used to support solar panels or wind turbines, which make these systems of renewable energy self-sustaining.

In addition, the lasting nature of custom metal brackets makes them able to sustain for many years, cutting down on the required replacements, while also aiding the sustainability of the project. This goes hand in hand with the lowered focus on the construction waste alongside the increased emphasis on using green construction materials in building designs.

Conclusion

In both architectural and industrial design, custom metal brackets are an irreplaceable element due to their amazing versatility, durability, and beauty. By means of custom sheet metal fabricating, designers are able to craft metal brackets needed for a wide scope of projects, which can range from extravagant industrial supports to artistically decorative ones featured on the exterior of the buildings. Their scope of purpose is definitely not limited to functionality, as they can be purely esthetic, but customizing the components will allow them to fit wonderfully into any design.The custom metal brackets industry is likely to evolve further due to the advancement of innovative and sustainable designs. The all-purpose nature alongside strength of these materials make them indispensable within modern architecture and industrial design as they aid in driving the boundaries of what can be achieved while ensuring the design's beauty is maintained alongside the structural integrity. Custom metal brackets and specialized sheet metal fabrication is the perfect answer towards stiff, unique, and functional structures which stand out, regardless if the scale is in regards to industrial projects or advanced architectural designs.