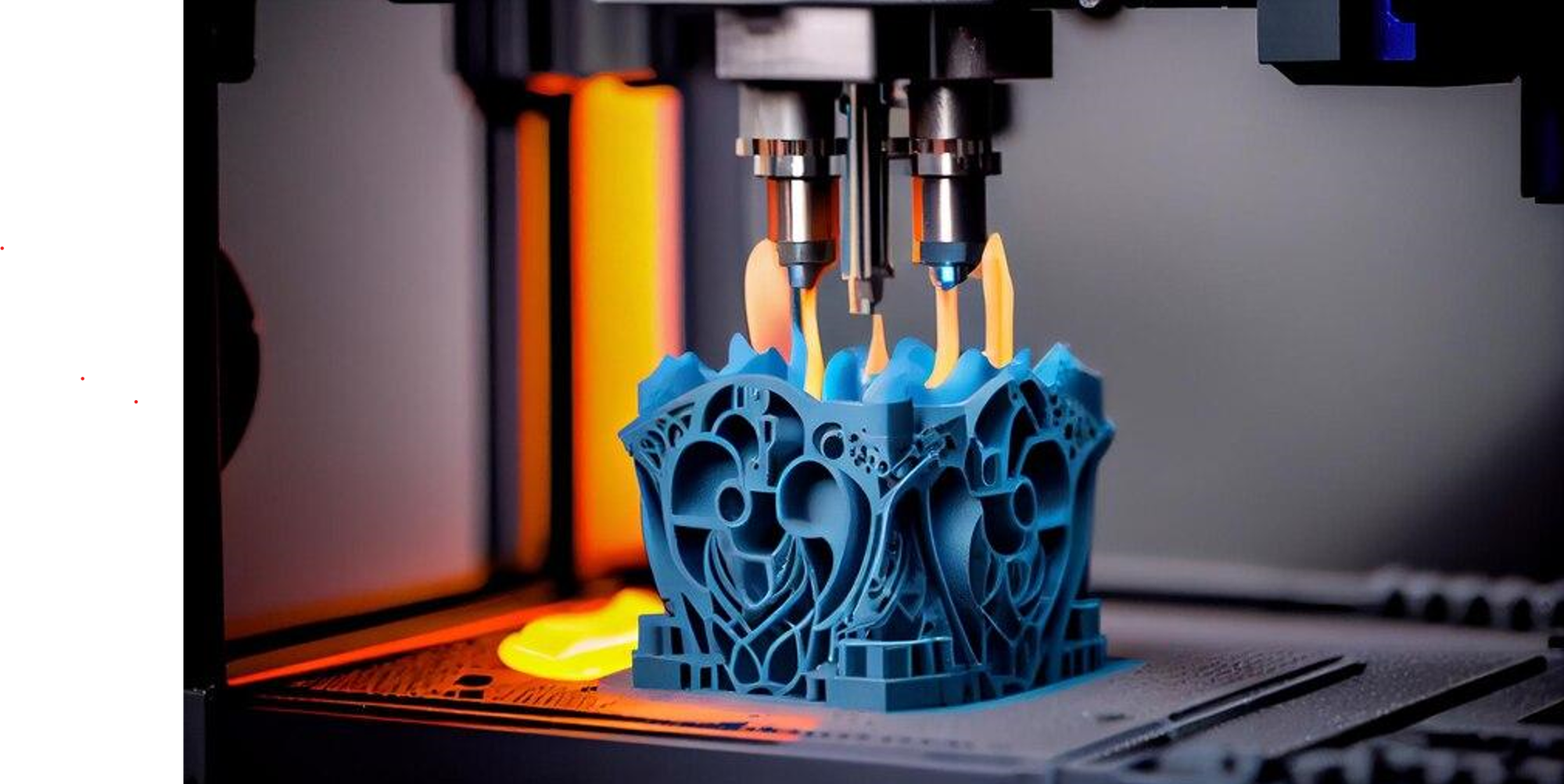

Best 3D Printing Materials for High-Quality Results

3D printing has come as a revolution for many industries in manufacturing. The idea that you could basically print out a 3D version or a prototype of your product prior and test it out was definitely transformative for companies globally. Historically speaking, 3D printing was simply an idea in 1981 and then it was launched, and companies appreciated it so much that it became, and still is, part of the daily life at work for many people.

Needless to say, the first version that Hideo Kodama created was more simplistic than the 3D printers we have nowadays. The evolution of 3D printing from the ‘80s to the one we know now has transformed the first device that only had a few basic commands to the advanced multi feature ones we have in 2024.

One of the things that came with this evolution is the myriad diverse types of materials that you can print in. Choosing the right material to print in a 3D printer is crucial for qualitative results; hence, knowing the types of materials is necessary. In this article, we will have a look at the best 3D printing materials that are available today.

Polylactic Acid (PLA)

The polylactic acid (PLA) material is probably one of the most well-known ones that are popular and used by many manufacturers worldwide. There are a few characteristics that this material has which make it widely used, and they are:

- Biodegradability

- Colorful options

- Ease of use

In short, PLA is extremely easy to use and handled, it is available in various colors and probably most importantly, it is biodegradable. On that positive note, PLA comes from harmless resources such as sugarcane or corn starch. This material is used for different applications and is suitable to be used both by beginners and experienced users of 3D printers.

Acrylonitrile Butadiene Styrene (ABS)

The acrylonitrile butadiene styrene (ABS) material is also widely used in the 3D printing world. This material is mainly used because of its:

- Strength

- Durability

- Heat resistance

Probably the most important element that also makes it differ from the other materials is the heat resistance that ABS has. In that line, it has higher heat resistance levels than PLA. Nevertheless, since it resists high heat, it also emits stronger fumes when printing. Thus, the printing space should be well-ventilated when using ABS. Additionally, if treated with acetone after printing, it can transform into a glossy and shiny material for the end product.

Polyethylene Terephthalate Glycol (PETG)

Polyethylene terephthalate glycol (PETG) is the combination of the two materials above, so the PLA and the ABS. Technically, PETG is quite easy to work with just like PLA, and is very durable just like ABS. Some of its most prominent features are:

- Chemical resistance

- Excellent layer adhesion

- Impact resistance

PETG is the perfect material to be used when printing mechanical parts or plastic containers. Just like ABS, it also has a glossy finish so in the end it will be all shiny. However, in contrast to ABS, it can also be printed at lower temperatures. Chemical resistance means that the material can work in harsh environments and that’s definitely an advantage for PETG.

Polyamide (Nylon)

The polyamide (nylon) material is also among the best 3D printing materials that bring high-quality results. Nylon is best known for its:

- Toughness

- Flexibility

- Low friction

Similar to the other 3D printing materials discussed above, nylon is also well-known for the toughness of the material and the flexibility it offers which makes it perfect to be used in different applications. In contrast to PLA, ABS and PETG, nylon requires a wet bed when printing. In addition to that, ventilated spaces are necessary when using nylon for 3D printing, because the nylon material has a tendency for moisture absorption which can cause issues in the end product.

Thermoplastic Polyurethane (TPU)

The thermoplastic polyurethane (TPU) material due to its nature is mostly used for 3D printing shoes and prosthetics. Some of its best features are: Elasticity Abrasion resistance Shock absorption Apart from these, TPU is also resistant to oils and greases which makes its uses and applications even wider. Its elasticity is also a huge advantage because it is available in both soft and rubbery versions, but also harder material types.

Conclusion

In today’s world, just like there are different 3D tools, there are also different types of 3D printing materials. PLA, ABS, PETG, Nylon and TPU are the top 3D printing materials of today and their features are on the top. With the advancement of technologies, it is expected that in the future there will be even more diverse materials available that will further expand the capabilities of 3D printing. The future is definitely exciting for the 3D printing world, and we are here for it!